Standard Lead-Time: Ten (10) Business Days. Expedited service may be available.

Receiving and Evaluation

Pump, Compressor and/or any associated components are itemized and photographed.

Any damaged or missing components are noted.

Customer is required to provide details on any contamination that may be present in the pump and/or any associated components.

All items received are logged into the Lassen tracking system for trace-ability throughout the rebuild process.

Customer is contacted to advise of any damage or missing components that could add to the standard rebuild cost.

Disassembly

All rebuild-able items are disassembled to the major component level.

Components are inspected and all critical tolerances are measured.

Second-Stage 15k Charcoal Condensing Array is discarded.

Failure analysis report generated.

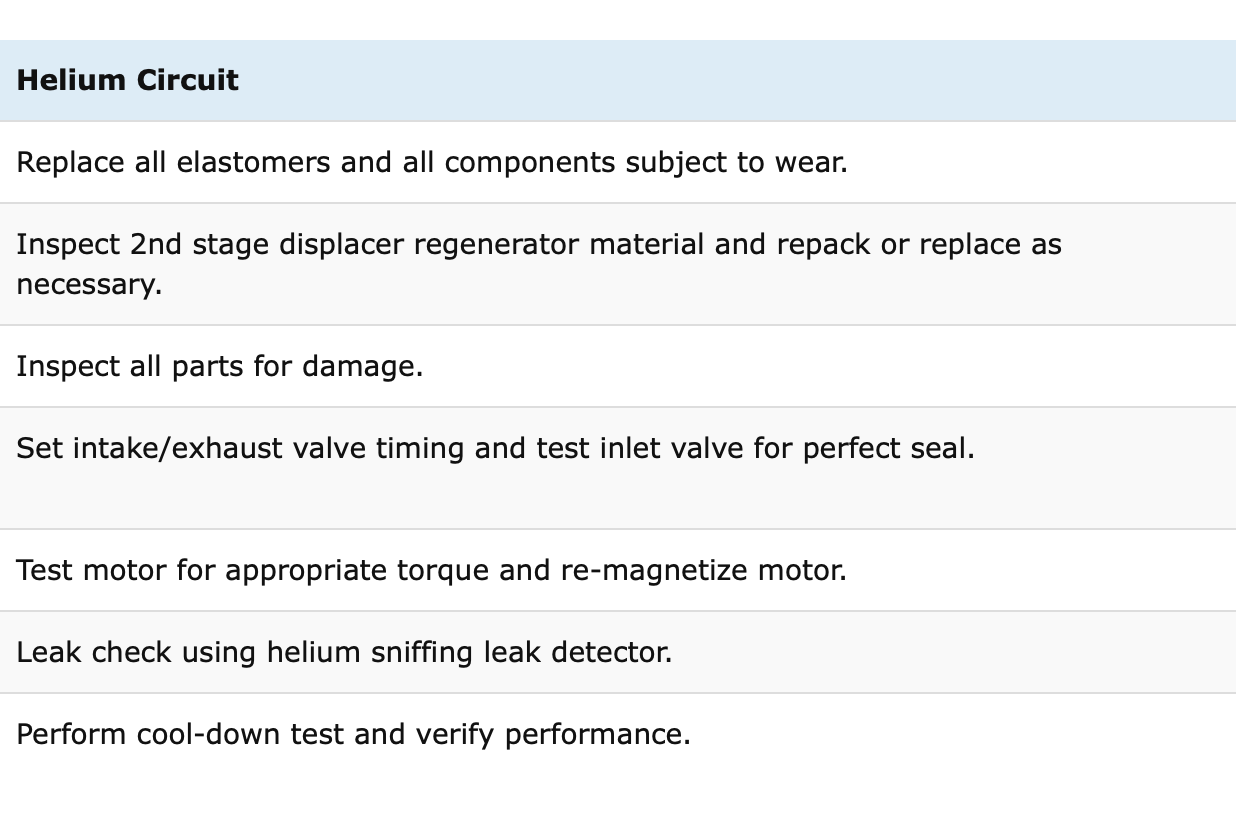

Reconditioning

All items are ultrasonically cleaned.

Decontamination procedures are performed as needed.

Radiation Pot is media blasted and repainted with low emissivity paint.

Frontal (first-stage) array is re-plated with electroless nickel.

New 15 Kelvin charcoal condensing array is installed.

On-board roughing valve assembly is refreshed as needed.

Other on-board modules are refreshed as needed.

Reassembly

All items re-assembled per original manufacturers specifications.

Test

Cool-down test (time vs. temperature) is performed. Performance results verified.

Motor vibration test.

Vacuum vessel leak checked with helium leak detector.

Hour meter is reset to zero (0) for on-board pumps.

Packaging and Shipment

Lassen rebuild identification tag applied to rebuilt item(s).

Item(s) are bagged and prepared for shipment.

REBUILDING FOR YOUR FUTURE

WE FOLLOW INDUSTRY-STANDARD BEST PRACTICES AND EXACTING STANDARDS

FOR ALL REBUILDS PERFORMED BY LASSEN